Noisy sliding doors can be a real headache. They disrupt quiet moments and make daily routines less enjoyable. Thankfully, the YF150 Automatic Door Motor offers a game-changing solution. It eliminates noise while improving the door’s smoothness. With this motor, anyone can transform their space into a quieter and more comfortable environment.

Key Takeaways

- Clean the sliding door tracks often to get rid of dirt. This easy task lowers noise and helps the doors slide smoothly.

- Switch to the YF150 Automatic Door Motor for quieter use. Its special design reduces noise, perfect for calm spaces.

- Take care of the motor by oiling moving parts regularly. This keeps it working longer and improves how it runs.

Common Causes of Noise in Sliding Doors

Sliding doors are convenient, but they can become noisy over time. Understanding the root causes of this noise can help fix the problem effectively. Let’s explore the most common culprits.

Dirt and Debris in the Track

One of the biggest reasons sliding doors make noise is dirt and debris in the track. Dust, grime, or small particles can build up over time, creating friction that disrupts smooth movement. This not only makes the door noisy but also harder to operate.

To tackle this, cleaning the tracks regularly is essential. A vacuum cleaner or a stiff brush works wonders for removing obstructions. For stubborn grime, a damp cloth can help restore the track’s smoothness. Keeping the tracks clean ensures the door glides effortlessly, reducing noise significantly.

Tip: Consider using a silicone-based lubricant after cleaning to further minimize friction and noise.

Worn-Out or Misaligned Rollers

Rollers play a crucial role in how smoothly a sliding door moves. Over time, these rollers can wear out or become misaligned, leading to squeaking or grinding sounds. Damaged rollers also make the door harder to slide, which can be frustrating.

Inspecting the rollers for wear and tear is a good starting point. If they’re damaged, replacing them with high-quality rollers can make a big difference. Upgrading to larger wheels can also improve weight distribution, reducing noise and enhancing the door’s performance.

Motor or Mechanism Issues

If your sliding door uses an automatic system, the motor or mechanism might be the source of the noise. Older motors or poorly maintained mechanisms can produce grinding or buzzing sounds.

Switching to a modern solution like the YF150 Automatic Door Motor can solve this issue. Its brushless motor technology ensures silent operation, making it ideal for noise-sensitive environments. Regular maintenance, such as lubricating moving parts and inspecting components, can also keep the motor running smoothly for years.

By addressing these common causes, you can enjoy a quieter, more efficient sliding door experience.

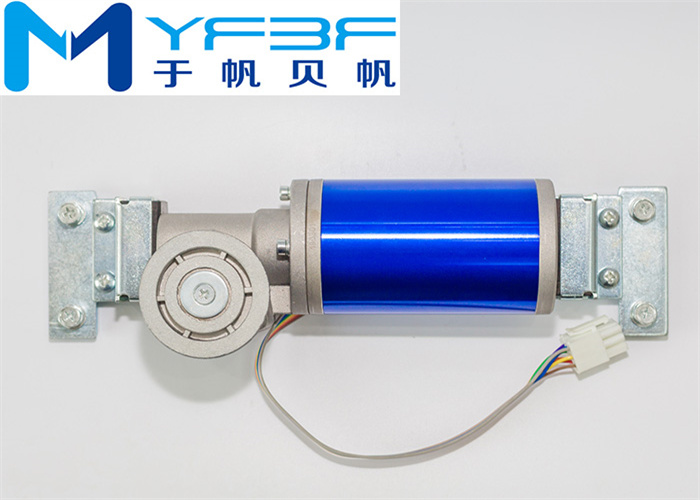

Why the YF150 Automatic Door Motor is the Ideal Solution

Silent Operation with Brushless Motor Technology

Nobody likes a noisy sliding door, especially in quiet spaces like offices or hospitals. The YF150 Automatic Door Motor solves this problem with its advanced brushless motor technology. This design eliminates the friction caused by brushes in traditional motors, resulting in a quieter and smoother operation. Whether it’s a bustling shopping mall or a serene hotel lobby, this motor ensures minimal noise disruption.

The YF150 also uses a helical gear transmission system. This feature enhances stability and reduces vibrations, further contributing to its silent performance. With a noise level of ≤50dB, it’s quieter than most household appliances. Here’s a quick breakdown of the technical features that make this motor so quiet:

| Feature | Description |

|---|---|

| Motor Type | Brushless DC motor, small size, high power, low noise operation |

| Gear Transmission | Helical gear transmission for stable and reliable operation |

| Noise Level | Lower noise than traditional brush motors |

| Efficiency | High transmission efficiency, large output torque, low noise |

| Reliability | Better reliability due to brushless technology |

This combination of cutting-edge technology and thoughtful engineering makes the YF150 a top choice for anyone looking to reduce noise in their sliding door systems.

Durability and Longevity (Up to 3 Million Cycles)

Durability is another standout feature of the YF150 Automatic Door Motor. Unlike traditional motors that wear out quickly, this motor is built to last. It boasts a lifespan of up to 3 million cycles, which translates to roughly 10 years of consistent use. This longevity makes it a cost-effective investment for both residential and commercial spaces.

The motor’s brushless design plays a big role in its durability. Without brushes to wear down, the motor experiences less internal friction, which extends its operational life. Additionally, the worm gear transmission maximizes efficiency while minimizing wear and tear. This ensures the motor can handle heavy doors without compromising its performance.

For businesses like airports or shopping malls, where doors operate thousands of times a day, the YF150 offers unmatched reliability. It keeps doors running smoothly, reducing the need for frequent repairs or replacements.

Versatility for Various Door Types and Settings

The YF150 Automatic Door Motor isn’t just powerful and durable—it’s also incredibly versatile. It works seamlessly with a wide range of door types, including sliding doors, swing doors, curved doors, and even telescopic systems. This flexibility makes it suitable for diverse environments, from hospitals to office buildings.

Its compact design and high power output allow it to handle both lightweight and heavy doors with ease. Whether it’s a sleek glass door in a modern office or a robust metal door in an industrial setting, the YF150 adapts effortlessly. The motor also supports customization, including color options, to match specific architectural designs.

This versatility extends to its installation process. The motor comes with an easy-to-use installation bracket, making it simple to set up in various settings. Its Hall signal output ensures precise control, while JST terminals provide secure and reliable connections. These features make the YF150 a practical choice for anyone upgrading their automatic door systems.

Tip: For optimal performance, pair the YF150 with regular maintenance, such as cleaning tracks and lubricating moving parts.

The YF150 Automatic Door Motor combines silent operation, durability, and versatility to deliver an exceptional sliding door experience. It’s a solution that works for everyone, whether they’re managing a busy commercial space or upgrading their home.

Step-by-Step Guide to Installing the YF150 Automatic Door Motor

Installing the YF150 Automatic Door Motor might seem challenging at first, but with the right tools and a clear plan, it becomes a straightforward process. This guide will walk you through each step to ensure a smooth and successful installation.

Tools and Materials Needed

Before starting, gather all the necessary tools and materials. Having everything ready will save time and make the process more efficient. Here’s a checklist of what you’ll need:

- Screwdrivers (Phillips and flathead)

- Power drill with appropriate bits

- Measuring tape

- Level

- Wrenches or spanners

- Wire strippers and crimping tools

- Silicone-based lubricant

- Cleaning supplies (vacuum, brush, and cloth)

- Installation manual for the YF150 Automatic Door Motor

Note: Ensure the motor complies with safety standards like IEC or NEMA ratings. Motors installed at height may require special insulation, and those exceeding 60°C need guarding. Always check the motor nameplate for visibility after installation.

Having these tools on hand will make the installation process smoother and safer.

Preparing the Sliding Door for Installation

Preparation is key to a successful installation. Start by inspecting the sliding door and its components. Look for dirt, debris, or damage that could interfere with the motor’s operation.

- Clean the Tracks: Use a vacuum or brush to remove dust and grime from the tracks. Wipe them down with a damp cloth for a thorough clean.

- Inspect the Rollers: Check the rollers for wear or misalignment. Replace them if necessary to ensure smooth movement.

- Measure and Mark: Use a measuring tape and level to mark the motor’s mounting position. This ensures proper alignment during installation.

Tip: If the door is heavy, consider enlisting help to avoid injuries during the preparation phase.

Installing the YF150 Automatic Door Motor

Now it’s time to install the motor. Follow these steps carefully to ensure everything is set up correctly:

- Mount the Motor: Attach the motor to the designated bracket using screws and a power drill. Make sure it’s securely fastened and aligned with the door’s movement.

- Connect the Wiring: Use wire strippers to prepare the wires. Connect them according to the installation manual, ensuring a secure and reliable connection. Avoid using wire nuts; instead, opt for metal junction boxes for added safety.

- Attach the Drive Mechanism: Connect the motor to the door’s drive mechanism. This step may vary depending on the door type, so refer to the manual for specific instructions.

- Secure the Components: Double-check all screws, bolts, and connections. Tighten them as needed to prevent any loose parts.

Safety Reminder: For motors above 55 kW, use RTDs and temperature relay systems to monitor performance. Always notify a certified engineer for special usage cases.

Testing and Adjusting for Optimal Performance

Once the motor is installed, testing and adjustments are crucial to ensure it operates smoothly. Here’s how to do it:

- Power On the Motor: Turn on the power supply and observe the motor’s initial operation. Listen for unusual noises or vibrations.

- Test the Door Movement: Open and close the door several times to check its alignment and smoothness. Adjust the motor’s settings if needed.

- Fine-Tune the Speed: Use the control panel to adjust the door’s opening and closing speed. This ensures it meets your specific requirements.

- Lubricate Moving Parts: Apply a silicone-based lubricant to the tracks and rollers for quieter and smoother operation.

Pro Tip: Place clear signage near the motor to prevent reverse-rotation hazards and ensure safety for all users.

By following these steps, you’ll have a fully functional YF150 Automatic Door Motor that operates efficiently and quietly. Regular maintenance will keep it running smoothly for years to come.

Maintenance Tips for the YF150 Automatic Door Motor

Proper maintenance is essential for keeping the YF150 Automatic Door Motor running smoothly and extending its lifespan. Here are some practical tips to ensure optimal performance.

Regular Cleaning of Tracks and Rollers

Dust and debris can accumulate in the tracks and rollers, causing friction and noise. Regular cleaning prevents these issues and ensures smooth door movement. Use a vacuum or a stiff brush to remove dirt from the tracks. For stubborn grime, a damp cloth works well. After cleaning, inspect the rollers for wear or misalignment. Replacing damaged rollers can prevent further complications.

Tip: Preventive maintenance minimizes unexpected breakdowns and downtime. According to studies, optimized cleaning schedules improve overall equipment effectiveness (OEE).

| Maintenance Strategy | Impact on Performance |

|---|---|

| Preventive Cleaning | Reduces friction, ensuring smoother operation. |

| Optimized PM | Prevents unplanned outages and enhances reliability. |

Lubricating Moving Parts

Lubrication is vital for reducing friction and wear in moving parts. Apply a silicone-based lubricant to the tracks, rollers, and other components. This not only ensures quieter operation but also protects against corrosion.

Studies highlight the importance of proper lubrication. Contaminated or inadequate lubrication can lead to excessive friction and accelerated wear. Reliable lubrication extends the motor’s life, minimizes failures, and reduces maintenance costs.

- Lubricants reduce friction, prevent corrosion, and improve heat transfer.

- Incorrect lubricant selection can cause metal-to-metal contact, leading to equipment failure.

- A rigorous lubrication program ensures reliable operation and protects the system.

Periodic Inspection of the Motor and Components

Regular inspections help identify potential issues before they escalate. Check the motor, wiring, and connections for signs of wear or damage. Scheduled diagnostics ensure timely repairs, improving efficiency and extending the motor’s lifespan.

Preventive measures, such as early troubleshooting, minimize damage to the system. Regular testing and documentation also contribute to better performance tracking.

- Inspections prolong motor life and ensure optimal performance.

- Scheduled maintenance prevents costly repairs and unplanned downtime.

- Keeping records of maintenance activities helps track the motor’s condition over time.

By following these maintenance tips, users can enjoy a reliable and efficient sliding door system for years to come.

The YF150 Automatic Door Motor offers a simple yet powerful way to fix noisy sliding doors. Its silent operation, durability, and versatility make it a standout choice for homes and businesses alike. Proper installation and regular maintenance ensure it performs at its best for years. Why wait? Upgrade today and enjoy quieter, smoother doors!

FAQ

What makes the YF150 motor quieter than traditional motors?

The YF150 uses brushless motor technology and helical gear transmission. These features reduce friction and vibrations, ensuring silent operation with noise levels below 50dB.

Can the YF150 motor handle heavy sliding doors?

Yes! The YF150’s worm gear transmission provides high torque, allowing it to handle heavy doors effortlessly. It’s perfect for both lightweight and industrial-grade doors.

How long does the YF150 motor last?

The YF150 motor lasts up to 3 million cycles, or about 10 years, with proper maintenance. Its brushless design ensures durability and long-term reliability.

Tip: Regular cleaning and lubrication can extend the motor’s lifespan even further!

Post time: Jun-11-2025